High-Performance Fuel Polishing Systems

Your Emergency Fuel System Depends on Clean Fuel

When business continuity depends on the reliable performance of your fuel transfer system (FTS) to power your emergency generators, the fuel in your FTS must be of optimal quality. Fuel can become contaminated with dirt, rust, and other types of sediment that clogs the filtration system and wears down the mechanical components of your FTS.

Proper fuel maintenance will help keep your fuel supply system operating at peak performance and reduce your equipment repair and replacement costs by extending the life of your fuel transfer system. Since 1996, ISP has been completed hundreds of mobile fuel polishings for hospitals, financial institutions, schools, sports arenas, data centers, and other mission-critical facilities.

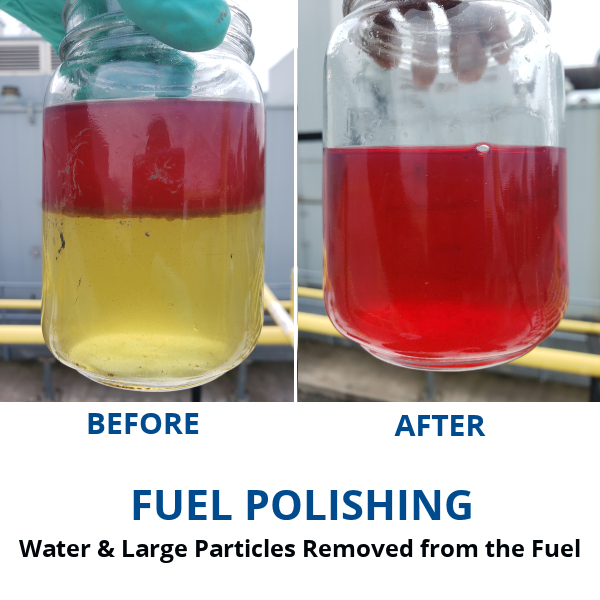

What Is Fuel Polishing?

Fuel polishing is a technical cleaning process that uses filters, and coalescers to remove contaminants like water, dirt, sediment, and microbes from diesel and other fuels. Fuel polishing systems maintain fuel at optimal quality to protect your fuel transfer system and emergency generators from becoming damaged and inoperable. During the fuel polishing process, fuel is continually circulated from the tank through a mobile filtration system that can fit through most standard doorways and elevators.

The mobile filtration system is designed to remove water, sludge and sediment before returning the fuel back into the tank. One of the benefits of using a mobile system is the ability to target certain sections of the tank where water, sludge and sediment are found. It is recommended to run the total amount of fuel through the system 2-3 times over for best results.

What Companies and Facilities Need a Fuel Polishing System?

Any facility that stores a large volume of fuel on-site will benefit from a fuel polishing system. The fuel stored for use by your fuel transfer system is a critical asset needed to prevent potentially catastrophic facility shutdowns. The most accurate way to find out if your fuel supply is contaminated is to have it tested.

ISP has been the trusted source for fuel analysis among mission-critical facilities worldwide since 1996. Our fuel analysis lab enables us to quickly sample your diesel fuel and provide you with analysis of its condition. We get your results as quickly as possible to facilitate immediate corrective actions to remediate your fuel’s quality. Our fuel quality experts have the knowledge and experience to provide you with recommendations to improve fuel quality.

Who Needs ISP’s Fuel Transfer System Solutions?

Mission Critical Fuel Transfer System Solutions

Organizations trust ISP Fuel Transfer Systems to safeguard their ability to perform critical services during power outages. In many cases, our fuel transfer systems protect the wellbeing of people whose lives depend on crucial medical services. From medical centers, financial institutions and data centers to schools and stadiums, ISP has created unique fuel transfer system solutions that ensure a readily available, usable fuel supply for the mission-critical systems of organizations throughout the world.

- Hospital and Medical Centers

- Data Centers

- Financial Institutions

- Schools

- Government Facilities

- Stadiums and Arenas

Top 5 Reasons Companies Depend on ISP for for Fuel Polishing

Expertise

For over 25 years, ISP has been the trusted expert providing exceptional fuel polishing systems to mission-critical facilities across various industries. Our knowledgeable and experienced team will assess your needs and provide you with an efficient and effective fuel polishing solution to keep the fuel you depend on to power your emergency generators in top-notch condition.

Dependability

At ISP, we know it’s crucial to keep your fuel transfer system in peak condition to help you avoid potentially disastrous facility shutdowns. Our clients know they can depend on us to provide dependable and efficient fuel polishing systems that keep their backup fuel supply clean and ready to use.

Dedication to Excellence

We’ve earned an outstanding reputation throughout the nation for our 100% dedication to providing mission-critical facilities with high-quality fuel polishing systems that help keep their crucial operations running smoothly.

Responsive

The ISP team is ready to provide you with fuel polishing solutions when you need them most. Our fuel filtration systems are the solution you need to keep your fuel transfer system and emergency power generators running efficiently to avoid operational shutdowns.

Outstanding Customer Support

The ISP team prides itself on being a leading fuel analysis company and collaborative partner to our clients. We help safeguard their crucial operations so they can build successful, long-term businesses.

Learn How ISP Can Help Your Business Succeed

We’d love to discuss with you how our unique fuel transfer solutions can help your organization be successful. Let us show you how a long term relationship with ISP Fuel Systems can ensure that your fuel supply system needs are always a priority.

Get Started

Call ISP at 732-951-9540 or email sales@ispfuelsystems.com to get started!