Reliable Fuel Transfer System Maintenance, Service and Repair

FTS Service and Repair

For more than 25 years, organizations throughout the world have depended on ISP Fuel Systems to provide them with dependable service, maintenance and repair to keep the fuel transfer systems (FTS) that support their emergency generators up and running and avoid potentially disastrous interruptions in their ability to provide essential services during power outages. Our fuel transfer system preventative maintenance experts have helped keep emergency generators and other mission-critical applications running smoothly for organizations such as hospitals, data centers, financial centers, schools and stadiums. Our decades of experience, specialized industry knowledge, and outstanding reputation have made ISP the fuel transfer system service company trusted by organizations nationwide to provide skillful, timely FTS maintenance and repairs for their emergency fuel systems.

Timely and Cost-Effective Fuel Transfer System Service, Maintenance and Repair

We Service and Repair FTS Equipment From All Manufacturers

If your organization depends on power to provide critical medical, financial, educational, governmental, or other public and private services, you can’t risk an interruption in your workflow. Depend on ISP’s team of professional fuel transfer system service, maintenance and repair experts to keep your fuel supply system fully functional and help you avoid downtime that could have disastrous outcomes.

Fuel Transfer System Maintenance and Service

Your fuel transfer system needs regular preventative maintenance to keep operating efficiently and ensure it will be ready to supply fuel to your emergency generator in the event of a power outage. Diesel fuel tanks accumulate debris, sludge and water in them every time they’re refueled, and these contaminants accumulate at the bottom of your fuel tank and clog the system, causing it to perform inefficiently or not at all. In addition, your system’s pumpset, control panel, and other components need regular service so they’re ready and able to send fuel to your backup power generator. Don’t risk your business’s reputation and the health and safety of your employees and the environment. Depend on ISP Fuel Systems for convenient and reliable FTS maintenance and service.

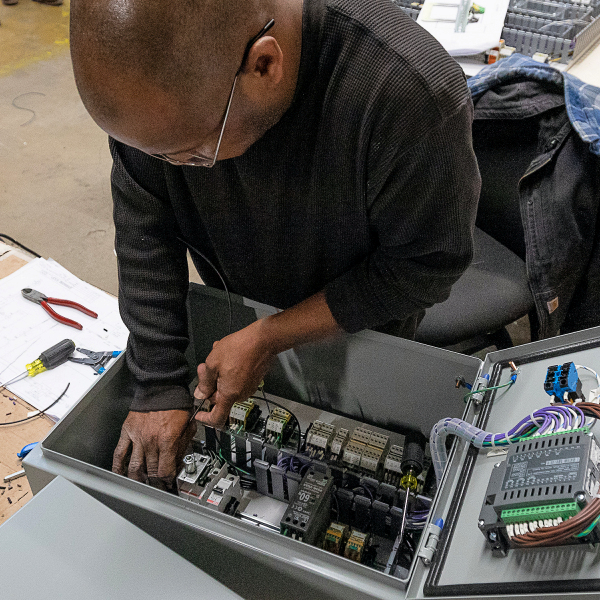

An ISP technician performs a routine equipment checkup on a Fuel Transfer System.

Reliable Preventative Maintenance Programs

SP offers flexible quarterly, semi-annual, and annual maintenance programs for fuel transfer systems from all manufacturers, regardless of whether we provided the original equipment. Our FTS service professionals conduct a complimentary system evaluation and recommend a preventative maintenance program tailored to your needs. By performing routine equipment checkups and regular maintenance, we ensure the integrity of your fuel transfer system. At each service visit, one of our professional FTS service technicians will conduct detailed inspection and testing of a portion of your fuel oil transfer system to keep it in top-notch condition:

- Tank Management Panels & Level Sensors:

- Visually inspect all wiring terminations

- Visually inspect pump start signal terminations

- Verify overload settings

- Check voltage to panel

- Test programmable logic controller

- Check and activate field inputs, assuring the PLC receives the appropriate signals

- Mechanical Components

- Inspect pipes, fittings and valves

- Start motors and check pump rotation

- Check to see that flow switches activate

- Cycle oil to header or day tank

- Control Panels

- Visually inspect all wiring terminations

- Visually inspect pump start signal terminations

- Verify overload settings

- Check voltage to panel

- Test programmable logic controller

- Check and activate field inputs, assuring the PLC receives the appropriate signals

- Valve Status – Manual & Motorized

- Manually open and close valves with limit switches to verify the master and remote panel receive the proper signals

- Cycle motorized valves open and closed from associated control panels

- Manually disengage fusible link valves and verify signals are received at the master and remote panels

- Filtration

- Check that Isolation valves are aligned

- Test additive low level

- Test pump leak switch

- Test filter DP alarm/Test strainer DP alarm

- DP Reading

- Clean strainers

- Test water storage tank full alarm

- Test water in fuel alarm

- Change filters

- Main Storage Tank/Day Tank/Header

- Conduct fuel sample analysis

- Visually inspect piping, gauges, etc.

- Cycle tank selection valves

- Cycle header selection valves

- Manually stick all tanks to verify accuracy of gauging components

An ISP technician replaces a circuit board.

Fuel Transfer System Repair

When your aboveground or underground fuel storage tanks, filtration system, control panels, sensors, pipes, valves, pumpsets, or other mechanical components aren’t working correctly, you need a reputable, experienced team to provide you with timely and accurate repairs. ISP’s service team is known for our fast response time, precise assessments, and reliable repairs. We repair fuel transfer system equipment from any manufacturer, regardless of whether we provided the original equipment. Hundreds of organizations nationwide rely on ISP to provide them with expert repairs to keep their existing fuel systems fully functional and help them avoid system downtime that could have catastrophic results.

Who Needs ISP’s Fuel Transfer System Solutions?

Mission Critical Fuel Transfer System Solutions

Organizations trust ISP Fuel Transfer Systems to safeguard their ability to perform critical services during power outages. In many cases, our fuel transfer systems protect the wellbeing of people whose lives depend on crucial medical services. From medical centers, financial institutions and data centers to schools and stadiums, ISP has created unique fuel transfer system solutions that ensure a readily available, usable fuel supply for the mission-critical systems of organizations throughout the world.

- Hospital and Medical Centers

- Data Centers

- Financial Institutions

- Schools

- Government Facilities

- Stadiums and Arenas

Top 5 Reasons Companies Depend on ISP for Fuel Transfer System Maintenance, Service and Repair

Expertise

ISP’s expert team of fuel transfer team service professionals has been providing organizations in various industries with peace of mind that their crucial operations won’t be interrupted by power outages since 1996. Our seasoned maintenance and repair crew has earned us a reputation as a dependable, expert source of fuel transfer system services.

Dependability

At ISP, we understand that keeping your FTS operating as it should is essential in helping you avoid potentially harmful business shutdowns. Our clients know they can depend on us to provide accurate, affordable and timely fuel system maintenance, service and repairs.

Dedication to Excellence

ISP Fuel Services is known for top-notch FTS maintenance and repair services throughout the nation. Our team is 100% dedicated to keeping your fuel system operating at its peak to help you keep your mission-critical operations running smoothly.

Responsive Service and Repair

When your existing fuel transfer system becomes inefficient or inoperable, ISP can provide you with fast, skillful repairs to minimize system downtime and help prevent emergencies related to power loss.

Outstanding Customer Support

As your collaborative partner, ISP will help safeguard your organization and its crucial operations as you continue to build a successful business.

Learn How ISP Can Help Your Business Succeed

We’d love to discuss with you how our unique fuel transfer solutions can help your organization be successful. Let us show you how a long term relationship with ISP Fuel Systems can ensure that your fuel supply system needs are always a priority.

Get Started

Call ISP at 732-951-9540 or email sales@ispfuelsystems.com to get started!